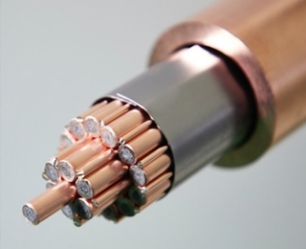

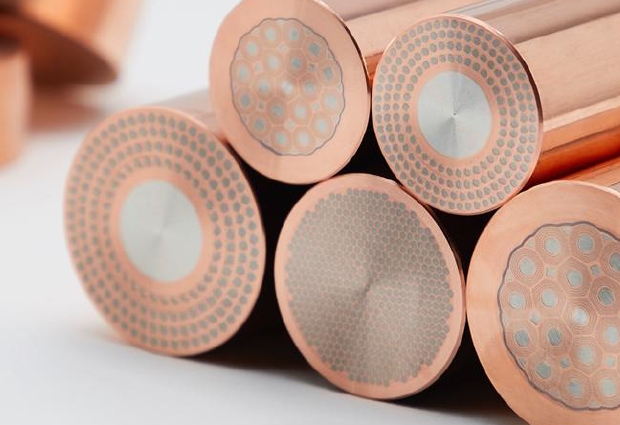

More than 3,000 fine Nb filaments are essential to improve the performances of Nb3Sn wires. Highprecision machining, gun-drilling and assembly technologies are required for the exact arrangement of filaments.

To reduce the diameter of filaments below 5 μm, two or more assembly processes using stacking technologies with several sub-elements are required.

Optimized surface cleaning is also necessary for enhancing the mechanical bonding between composite materials.

Gun-drilling process with precise machining tolerances for inserting filaments

Exact assembly and stacking of arranged sub-elements

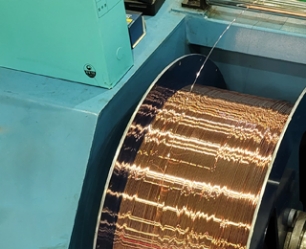

KAT is capable of manufacturing 10 km or longer length wires. To make a long length wire, KAT has straightening technology of sub-elements prior to the final restacking assembly.

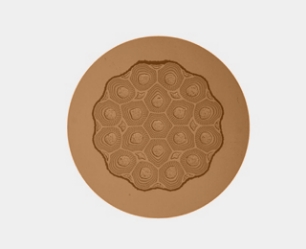

Ti doping is necessary to achieve a high critical current density. KAT has facilities for manufacturing Ti-doped Sn alloy by vacuum casting.

Consistent straightening and cutting sub-elements

Vacuum casting for refinement and homogeneous distribution of SnTi alloy

(SnTi alloy with controlled particle size and composition)

KAT manufactures stable and uniform wires by using swaging, cold drawing, groove rolling and extrusion. Uniform mechanical properties of the constituent materials are required for uniform deformation of wires.

As Nb3Sn wires for fusion reactors are used in the form of a cable conductor, metal insulation is necessary to reduce AC loss. KAT has a technology for uniform plating Cr or Ni on superconducting wires to the thickness according to customers’ requirement.

Bare and Cr plated Nb3Sn wires

Nb3Sn Wire

Nb3Sn Wire High Jc Nb3Sn Wire

High Jc Nb3Sn WireThe most commonly used wires for fusion reactors are manufactured with a diameter of 0.82 mm, the critical current of 250 A to 360 A at 4.2 K, 12 T, and the magnetization loss less than 1,000 mJ/cc.

High Jc Nb3Sn wire with a higher critical current is designed to have a critical current of 600 A or more and an effective diameter less than 50 μm with the same diameter.

| Number of Filaments | Cu/NonCu | Bare Diameter (mm) | Critical Current Density (Jc @4.2K) |

Qh mJ/cc (±3T) | RRR | |

|---|---|---|---|---|---|---|

| 12T | 16T | |||||

| > 3,000 | 1.0 ± 0.1 | 0.82 ± 0.005 | > 900 | > 400 | < 600 | > 100 |

| > 3,000 | 1.0 ± 0.1 | 0.82 ± 0.005 | > 1,200 | > 500 | < 1,000 | > 100 |

| > 25,000 | 1.0 ± 0.1 | 1.0 ± 0.005 | > 2,500 | > 1,200 | - | > 150 |

According to customer requirements, our products can be supplied in various specifications.